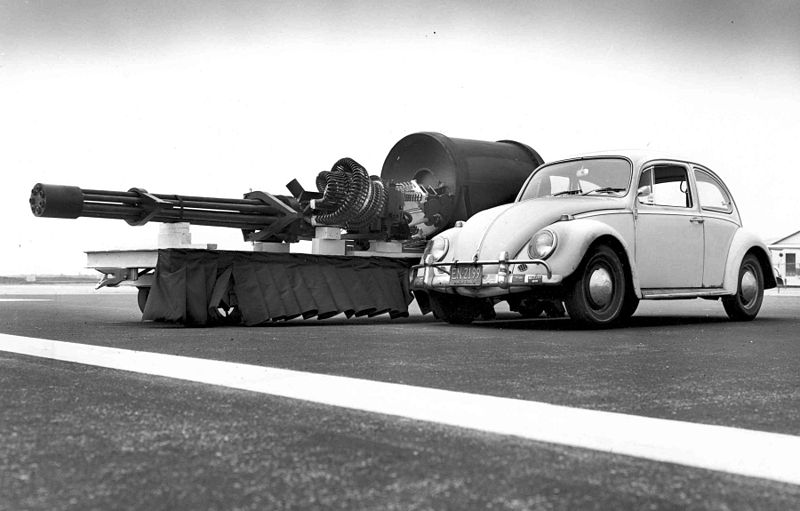

HHI Corporation of Farmington, UT approached us about helping them design a firing range for medium-caliber aircraft Gatling guns at Hill Air Force Base. In addition to 20-mm guns used on the A3 Cobra helicopters and F-16, the range had to accomodate the 30-mm GAU-8 Avenger, the anti-tank gun that the A-10 Thunderbolt Warthog was built around. The seven-barrel gun has a maximum firing rate of 4200 rounds per minute. Previous attempts to design a range had resulted in the conclusion that the muzzle blasts were so intense they would create significant concrete spallation. Consequently, guns removed from the aircraft for servicing were loaded on pickups, driven to the Utah Test and Training Range (4 hours round trip), installed, fired, dismantled, and returned to base. The ongoing logistical difficulty prompted the Air Force to again seek an indoor, on-base solution for testing the serviced weapons.

Testing the Gun

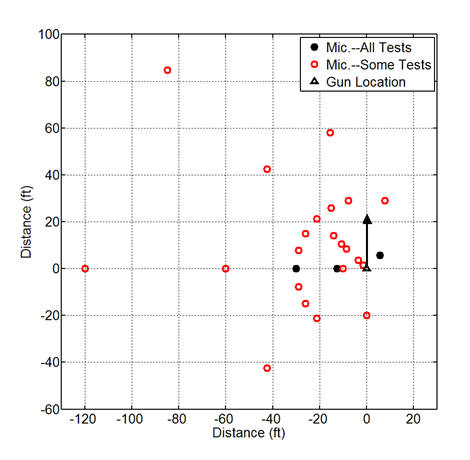

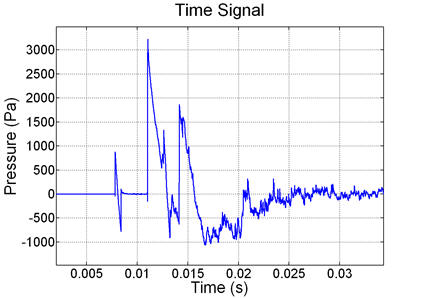

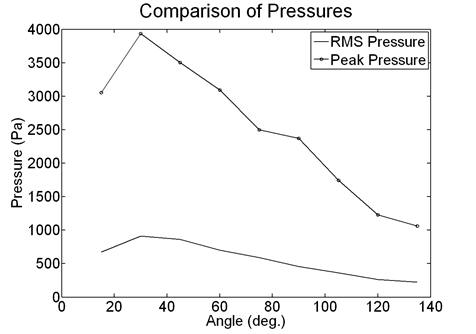

The Acoustics Research Group traveled to the Utah Test and Training Range to obtain-near-source measurements of the gun. A large array of microphones was used to obtain directivity measurements and to examine the shock decay with distance. The figure shows the shell sonic boom, the muzzle blast, the ground-reflected sonic boom, and the ground-reflected muzzle blast.

Modeling the Room

Armed (heh, heh) with an understanding of the gun's directivity, we needed to ensure that the peak pressure on the range's concrete surfaces were less than less than the prescribed limit. A room acoustics model of the proposed range was used to account for the reverberation. The figure below shows the range in Google Sketch up and in the computer package, EASE.

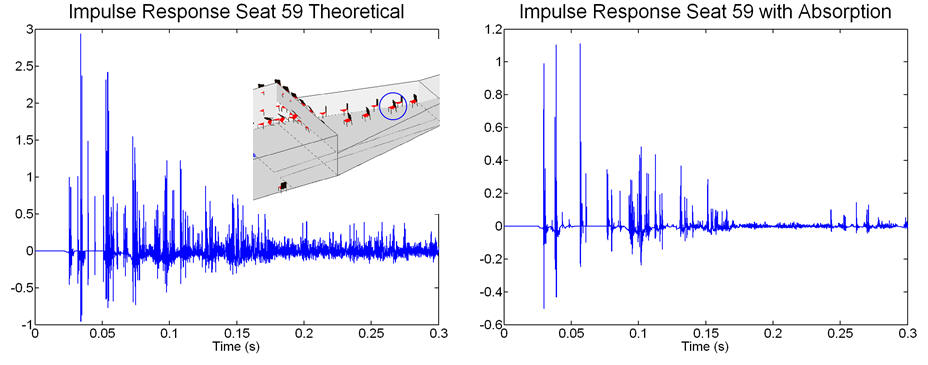

The impulse response with and without absorptive treatments was convolved with single and repeated muzzle blasts to ensure the peak pressures were sufficiently low. The transmission loss of the absorptive materials was tested to understand what the muzzle blasts would look like behind the treatments.

Testing the Range

After the room was built and the guns installed, measurements were made to verify the peak pressures inside the room were low enough and that the sound levels in the hallways, control room, and machine shop around the range were safe. All design goals were met.

Additional Information

For additional details, see the Noise Control Engineering Journal article by M. D. Shaw and K. L. Gee. (Paper #43 in Publications).